Our Powders. Your Products.

Latest News

Sandvik completes the acquisition of Buffalo Tungsten

In a press release issued Monday, 04 December 2023, Sandvik announced

"Sandvik has completed the previously announced acquisition of Buffalo Tungsten, Inc. (BTI), a leading US based manufacturer of tungsten metal powder and tungsten carbide powder, primarily operating in North America."

In a press release concerning the agreement to acquire Buffalo Tungsten on 26 October 2023, Sandvik said

"Sandvik has signed an agreement to acquire Buffalo Tungsten, Inc. (BTI), a leading US based manufacturer of tungsten metal powder and tungsten carbide powder, primarily operating in North America. The company will be reported within the business area segment Sandvik Machining Solutions (SMS).

"With the acquisition of BTI, Sandvik further expands its presence in the North American market and strengthens its regional capabilities in the component manufacturing value chain. The integration of BTI offers synergy potential, by optimizing materials sourcing and increasing the rate of locally produced tungsten metal powder, through its facility in Depew, NY, US. This will complement Sandvik’s already existing production of similar products at Wolfram in St. Martin, Austria.

"With the acquisition of BTI we take an important step in our strategic ambition to strengthen our presence in the North American market. BTI will enhance our regional capacity to produce tungsten powder locally in US, which will improve our competitive position,” says Stefan Widing, President and CEO of Sandvik.

“With BTI we will be able to better meet the customer demand which will give us great opportunities in North America. BTI’s contract for clean hydropower from the Niagara Power Project will also enable us to manufacture tungsten in a more sustainable way,” says Nadine Crauwels, President of Sandvik Machining Solutions.

"BTI was established in 1987, has 48 employees and is headquartered in Depew, New York. In 2022, the company generated revenues of about SEK 333 million. The impact on Sandvik’s EBITA margin will be limited. Impact on earnings per share will be accretive. The parties have agreed not to disclose the purchase price. The transaction is expected to close in the fourth quarter of 2023."

ITIA Membership

Buffalo Tungsten has applied for membership in the International Tungsten Industry Association (ITIA). We have filled out the membership application and also have letters supporting us from several member companies. Following the formal application process, the final step is a vote of the current members of the ITIA at the next annual general meeting. It will be in Brussels, Belgium in October. Tungsten is a small industry, therefore we already have business relationships with many of the member companies. As a result, we are hoping that the existing members will accept us into this esteemed organization.

ITIA Membership Goals

According to their website, the goals of the ITIA are

- to promote the use of tungsten and tungsten products

- to co-ordinate the extensive work programme of the ITIA Health, Safety and Environment Committee, including:

- regulatory and classification issues,

- monitoring proposed legislation,

- developing scientific data on the impact of tungsten on human health and the environment,

- in response to the EU's legislation "REACH", ITIA has set up a Tungsten Consortium which is open to Association members and non-members alike

- to organise regular meeting for the tungsten industry worldwide

- to collate from different sources, comprehensive statistics covering tungsten production, processing, consumption and end-uses and to circulate an annual statistical report to its members.

- to collate and circulate on a regular basis information relating to the ITIA's activities and to arrange for publication of a periodic newsletter

- to liaise and exchange information with other metal trade associations.

Refractory Metals Association

We have been a member of the Refractory Metals Association (RMA) since the beginning of 2021. This is a trade association of North American manufacturers. The purpose of this organization is "to promote and expand the markets for refractory metals."

Buffalo Tungsten has been producing tungsten powder products for 35 years. In addition to domestic sales, we sell tungsten powder in international markets, with sales in over 40 countries. We feel that our company is finally mature enough to be able to contribute to relevant trade organizations. As a result, we feel it is time to join the trade associations that allow us to help promote the industry and move it forward.

Buffalo Tungsten 35 Year Anniversary

Buffalo Tungsten recently celebrated our 35 year anniversary. A milestone such as this is an occasion to reflect on what got us to this point. There are several core values that have allowed our small private company to endure through the years. Here are a few of the things we feel have helped us achieve success.

First, Buffalo Tungsten maintains a strong focus on our customers. We do not make any fabricated tungsten products, so we have no internal demand. Our tungsten powder goes 100% into customer applications. We are not in competition with our customers, so we are able to focus on making powders that work for our customers without any conflict of interest.

High quality is a top priority in satisfying the needs of our customers. Our tungsten powder meets demanding customer specifications. Our quality assurance process assures conformance to physical and chemical requirements, such as

- Average Particle Size

- Particle Size Distribution

- Mesh Analysis

- Apparent Density

- Tap Density

- Chemical Purity

- Alloy Composition

The Extra Mile

In addition, we always try to go the extra mile to help our customers meet their production schedules. Buffalo Tungsten stocks many of the common powders our customers use, allowing us to provide short lead times. We are minutes from the Buffalo Niagara International Airport, and consequently we can get orders to the airport the same day to meet urgent requirements. We have made the trip many times on the way to the 35 year anniversary of Buffalo Tungsten.

Finally, competitive pricing is an important factor that allows us to achieve what we have. With a low cost facility and utilities we are able to provide value to our customers. We are always trying to increase efficiency in order to improve our competitive position.

In short, by putting the needs of our customers first we have made it our 35 year anniversary. After that long, we are still excited to continue to grow and improve. We look forward to seeing where the next 35 years takes us!

Russian Economic Sanctions

With the recent Russian actions in Ukraine, Russia is under economic sanctions by many nations. It is too soon to understand all of the impacts of these sanctions. Buffalo Tungsten is not reliant upon any Russian materials or supplies. We can operate at full capacity for tungsten powder production without any materials from Russian entities. We do not expect current or future Russian economic sanctions to effect our business.

There are active tungsten mines in Russia. They operate primarily in the far eastern part of the country, but there are tungsten operations in western areas as well. There are mines actively producing tungsten concentrates. The materials are available on the open market. There are plants in the country that treat and process these tungsten concentrates into various intermediate forms and products.

Buffalo Tungsten has purchased materials from Russian entities at times. We have no contracts in place for 2022 or beyond at this time to purchase materials reliant on Russian companies. Therefore, we feel that the Russian economic sanctions will not have an adverse impact on us.

Buffalo Tungsten's supply chain is diverse, but we still actively manage our sources of materials to insulate us from uncertainty. As a result, we have reduced our dependence on countries we feel present risks. We will continue to evaluate where we source raw materials. This will allow us to continue to provide a consistent supply of tungsten powder products to our customers.

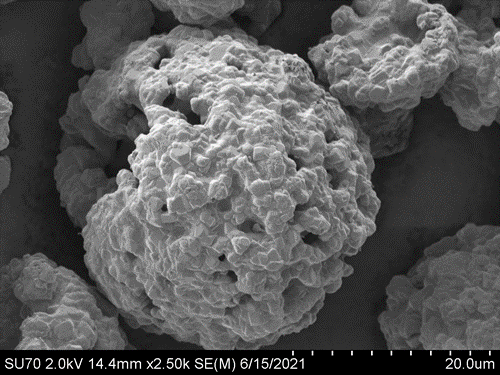

WC Thermal Spray Powder

Buffalo Tungsten's latest R&D project for WC thermal spray powder has led to some big improvements. We plan to launch the enhanced powders in the first quarter of 2022. Our new and improved products will help all who use our material see better results in their surface coatings.

The ASM International Thermal Spray Society has a page that describes the thermal spray process. It mentions that the powder is brought to a molten or semi-molten state and sprayed onto a part to restore and rebuild it or to provide a more protective surface coating. It can better protect the part from things like wear, abrasion, or corrosion. With this in mind, it is easy to see how the fine-tuning of our process will make a big impact on results.

Improvements to WC Thermal Spray Powder

Because the shape of the powder is so important, we have made our powder more spherical. As a result, our thermal spray powders flow better through the HVOF guns that apply it. Better flow through the gun allows for better application of the powder.

The deposition efficiency has also improved using our new process. This means that more of the powder ends up on the part and less on the floor. There is less waste and a more consistent surface coating.

In addition, the powders we are producing after the changes have a higher density. This gives the parts better wear and abrasion protection following a thermal spray coating.

Buffalo Tungsten is excited to introduce these changes. As with our other products, we manufacture WC thermal spray powder at our factory in Depew, New York. We welcome thermal spray shops to try our new powders and provide us with feedback. We listen carefully to our customers and always strive to make our thermal spray powders better meet your needs as we move forward.

Veterans Day

The US Department of Veterans Affairs (VA) has a page about the history of Veterans Day in the United States. The armistice to end the fighting of World War I went into effect at the 11th hour of the 11th day of the 11th month of 1918. As a result, we celebrate the veterans of our armed services each year on November 11th. At this time, Buffalo Tungsten would like to wish a happy Veterans Day to all who have served.

Unfortuantely, World War I was not the "war to end all wars," as many had hoped at the time. There have been many wars fought since then. As a result, it has been important to maintain our military to preserve our freedoms. Those who serve not only protect our nation, they also receive training that benefits their future career prospects.

At Buffalo Tungsten we encourage veterans to apply for job openings. We find that the skills they gain in military service help our company.

Reasons to Hire Veterans

The VA points out several reasons to hire veterans. The following ideas are from the VA:

- Working well in a team. Teamwork is an essential part of daily life and is the foundation of safe military operations.

- Having a sense of duty. Responsibility for job performance and accountability for completing missions are something to take pride in.

- Experiencing self-confidence. Holding a realistic estimation of self and ability based on experiences.

- Organization and discipline.

- Possessing a strong work ethic. In the military, the mission always comes first.

- Having the ability to follow through on assignments, even under difficult or stressful circumstances.

- Possessing a variety of cross-functional skills, such as extensive training on computer programs and systems, interacting with various people with different skills to accomplish a task, and coordinating and troubleshooting problems in novel and known conditions.

- Solving problems quickly and creatively.

- Adapting to changing situations.

- Able to follow rules and schedules.

On this Veterans Day Buffalo Tungsten is grateful to those who have served and currently serve in the armed forces of the United States. Without their service our company would not be able to operate ias we have for the past 34 years. We recognize and value the contribution of the US military on our ability to produce tungsten powder in a nation that is free. Our political and economic stability is a result of their dedication and service. We offer our thanks and well wishes for a happy Veterans Day to those who have earned that title of respect.

Buffalo Tungsten LED Lighting Upgrade

Buffalo Tungsten has recently upgraded lighting in our factory to LED fixtures. The change saves a substantial amount of electricity. "LEDs use up to 90% less energy and last up to 25 times longer than traditional incandescent bulbs" according to a US Department of Energy information page on LED lighting. It has also made a noticeable difference in the brightness of our factory.

There is a bit of irony in a tungsten factory is making an LED lighting upgrade. One one of the most widely known applications of tungsten is as a filament for the incandescent lightbulb. Some of the history of tungsten in lighting is in this article from the Institute of Electrical and Electronics Engineers. With the advent of LED lighting, the incandescent bulb is largely a thing of the past. General Electric closed their tungsten powder plant in Euclid, Ohio several years ago. For many years this plant made tungsten wire for the iconic GE light bulbs, which trace their roots back to Thomas Edison.

LED Lighting Upgrade More Efficient

This article from LED Lighting Info explains why the tungsten filament is inefficient. It states "around 90% of an incandescent bulb’s electricity supply is wasted as heat, with a measly 10% actually being used to create light. This is because the tungsten filament inside an incandescent bulb needs to be heated to around 4600 degrees Fahrenheit to produce light." It further goes on to explain that "when a 100-watt lamp is turned on, 100 watts of electrical energy is converted to 100 watts of light and heat. As incandescent bulbs are incredibly inefficient and have a luminous efficiency of 2-3%, this usually translates as 98 watts of heat and 2 watts of light."

The LED lighting upgrade also increases safety in our plant. Forklifts are easier to see as they move about the factory floor. Production equipment is easier to load and unload. It is easier to read tags and labels on our inventory, reducing eye strain.

While the tungsten powder market remains strong, it has shifted from lighting to other applications. With our transition to LED bulbs and fixtures complete, we sadly leave the tungsten filament behind.

Tungsten Powder Supply

In a time of global supply chain delays, the stability of your tungsten powder supply is critical. Buffalo Tungsten has taken steps to make sure that we have the materials you need available without additional lead time. We manufacture our tungsten powder products in the USA with raw materials sourced worldwide.

Buffalo Tungsten is able to use multiple types of raw materials to help assure a consistent tungsten powder supply. Our affiliate company Wolfram Bergbau und Hütten (Wolfram) can start with tungsten concentrates, scrap or sodium tungstate. Buffalo Tungsten can also start with intermediate products such as ammonium paratungstate and tungsten oxides. We have multiple suppliers of these materials. This ensures diversity in our supply chain so that we are not dependent on a single supplier. In addition to these steps, we have increased inventory to account for potential shipping delays.

As a result, there has been no interruption in our tungsten powder supply to our customers. We have been able to supply all of our powder products without delay throughout the COVID-19 pandemic. We have material available for existing customers and new customers alike.

Conflict Free Global Tungsten Supply Chain

The USA mines only trivial amounts of tungsten ore, so not all of our tungsten powder supply chain is domestic. As a result, we need to import raw materials from other countries. We receive materials from several continents.

Our supply chain contains only conflict free materials. Wolfram is a member of the Tungsten Industry - Conflict Minerals Council. Consequently, all of the materials we receive from them are from conflict free sources. Mines in conflict regions are subject to rigorous certification involving third party inspections.

If you are concerned about the availability of your tungsten powder supply, feel free to reach out to Buffalo Tungsten to see if we can offer the products you need. We would be happy to see if we can shorten your lead times and provide you with high quality tungsten powder products to meet your needs.

Powdered Tungsten Particle Size Distribution

At Buffalo Tungsten we measure our powdered tungsten's particle size distribution (PSD) in multiple ways. The Malvern Mastersizer has been our choice as a laser diffraction instrument for the past 25 years because it provides consistently repeatable and reproducible results. We made a recent upgrade in order to provide us with improved technology and software. Our commitment to high quality powder is supported by having the best testing equipment available.

A description from Malvern's website describes measuring particle size distribution by laser diffraction, saying "It does this by measuring the intensity of light scattered as a laser beam passes through a dispersed particulate sample. This data is then analyzed to calculate the size of the particles that created the scattering pattern. Three main elements enable the system to consistently and reliably deliver the accurate, robust particle sizing data that is central to the effective operation of so many industrial processes."

The Feedback Loop

At Buffalo Tungsten, frequent samples during our production process provide regular feedback. We measure all of the critical properties of the material. The Malvern Mastersizer can run samples dry, which reduces the time for sample preparation. Therefore, we can get fast results, which is essential for quality assurance.

The software is on our network to give our production team access to the data. This allows them to adjust furnace conditions as necessary. Doing so allows us to maintain the proper particle size and distribution in our finished powders. The faster we are able to change furnace conditions, the better the quality of the finished powder.

Not all tungsten powder applications have specifications for particle size distribution. For some the average size is specified but the distribution is not important. Some of our customers require a narrow monomodal tungsten particle size distribution around the mean for their material. However, some tungsten powder applications require bimodal or even trimodal distributions. The Malvern Mastersizer plays an important part in helping us meet these specifications.

Buffalo Tungsten's powdered metallurgy lab provides a complete certificate of analysis with each shipment of material. This assures that the tungsten metal powders we ship meet all customer requirements.

United States Geological Survey Tungsten Reports

The United States Geological Survey publishes statistics and information on tungsten. The monthly and annual tungsten reports contain a wealth of information on the tungsten market that can be found online at their website free of charge. They focus on the imports and exports of the United States, but contain additional information on the world tungsten market.

Mineral Industry Surveys are a monthly report that reflect the price of tungsten concentrates and the main tungsten intermediate ammonium paratungstate, or APT. The import and export data it reports both have the following headings, with the exception being that ferro-tungsten is not listed in the exports

| Ores and Concentrates | Ammonium Tungstates | Ferro-tungsten | Metal Powder | Tungsten Carbide Powder | Other | Total | Total Year to Date |

Annual Tungsten Reports

The Mineral Commodity Summaries provide a brief overview of the global tungsten market. It is an annual report with the following headings:

- Domestic Production and Use

- Salient Statistics—United States

- Recycling

- Import Sources

- Tariff

- Depletion Allowance

- Government Stockpile

- Events, Trends, and Issues

- World Mine Production and Reserves

- World Resources

- Substitutes

The Minerals Yearbook provides a more comprehensive annual report on the tungsten market. It has additional detail on things such as a world review of tungsten mining projects in numerous countries throughout the world. Additional tables on world tungsten production and usage is good background knowledge about markets on the world stage. Buffalo Tungsten and Niagara Refining are both reported as US processors of tungsten. The headings included in the report are:

- Legislation and Government Programs

- Production

- Consumption

- Prices

- Foreign Trade

- World Review

- Outlook

There are also some Special Publications that are of interest. Some of this information is a bit more dated, but it can be useful as background and provide historical information.

The Special Publications include things like

Historical Statistics for Mineral and Material Commodities in the United States

International Strategic Mineral Issues Summary Report - Tungsten

Those at the USGS over the mineral tungsten are some of the world's leading experts on the tungsten market. Please take advantage of their hard work as you learn more about the tungsten industry. While the tungsten reports are geared to the United States market, they have information that is helpful to a broad audience.