Our Powders. Your Products.

Latest News

Tungsten Pricing and Trade

Current Market Situation

2025 has been an interesting year in the tungsten market. In the current time of trade conflict, China restricted exports of tungsten materials with new licensing requirements. With the overall global supply constrained, prices are up about 250% since the beginning of the year, and have shown no signs of stopping. This post will review how tungsten pricing is determined and how material is traded.

Tungsten Pricing References

Although tungsten is a strategic mineral, it is also a minor metal. The demand for tungsten is low relative to base metals like nickel, zinc or lead. As a result, commodity exchanges do not trade tungsten ores, concentrates or other intermediary products. Trading occurs on a negotiated basis between the parties involved. Price references for tungsten concentrates are based on private transactions. Companies such as Argus Media, FastMarkets and Shanghai Metals Market have regular contact with industry sources to ask for current offer prices in the market and report a range with a high and low price. The price of APT is the most common reference material. Many long-term contracts will be based on the APT price in one of the published references.

Tungsten Ore Pricing

Tungsten ore is mainly in the form of wolframite ((Fe,Mn)WO4) or scheelite (CaWO4). Mines are typically underground hard rock mines, but there are several open pit tungsten mines operating. Up to 80% of the world's tungsten ore has historically been mined China. There are active mines throughout the world in Africa, Asia, Europe and South America.

Tungsten ores and concentrates sell on the basis of their tungsten oxide (WO3) content. The ore undergoes gravity separation to concentrate it at the mine. A chemical flotation process can remove additional impurities to increase the concentration before shipping. The industry standard for first grade tungsten concentrates is a minimum of 65% WO3. Lower grade concentrates may be available at reduced prices, but may need to be blended with higher grade concentrates.

Tungsten Concentrate Pricing

The level of specific impurities that are difficult to process also impact the value. Tungsten concentrates with high levels of elements such as arsenic and molybdenum or radioactive elements like thorium and uranium will be priced lower.

The trade in tungsten concentrates has decreased since many of the companies controlling the mine output have vertically integrated to produce tungsten intermediates. China has prohibited the export of tungsten concentrates for many years to sell value added intermediate products, allowing them significant control over pricing. The most common of the intermediates are ammonium paratungstate (APT), ammonium metatungstate (AMT) and tungsten oxides such as yellow tungsten oxide (YTO) and blue tungsten oxide (BTO).

Units of Trade

In international markets the unit of measurement for tungsten concentrates is the metric ton unit, or mtu. An mtu is 1% of a metric ton. Both tungsten concentrates and intermediates such as APT, BTO and YTO use the mtu as the standard measure.

One Metric Ton (MT) = 1000 kg

One Metric Ton Unit (mtu) = 10 kg

Being sold on the basis of the tungsten oxide (WO3) content, 1000kg of concentrate containing 65% WO3 would be valued at 650kg of WO3 content. The value of the shipment would commonly be 650kg x APT Price.

Buffalo Tungsten and our affiliate Wolfram purchase both tungsten concentrates and tungsten intermediates. If you have these materials available you can contact us.

Happy Thanksgiving to the Tungsten Powder Market

Navigating a Year of Turmoil in the Tungsten Powder Market with Gratitude

The Thanksgiving Holiday in America gives us an opportunity to reflect on the past year. As we do so, one word rises above the challenges, uncertainty, and volatility that defined the tungsten powder and tungsten carbide markets: gratitude.

The turbulence in global supply chains and unprecedented price swings tested the resilience of our industry. Yet through every twist and turn, we found strength not in the markets themselves, but in the people who stood beside us.

To Our Customers

Your trust has been our anchor. Even in times when the future seemed unclear, you continued to place confidence in our products, services, and commitment to quality. Your feedback guided us, your patience sustained us, and your loyalty reminded us why we do what we do.

To Our Colleagues

This year demanded adaptability, creativity, and endurance. Our team rose to the occasion with remarkable dedication. From engineers ensuring precision under pressure, to logistics experts navigating disrupted supply chains, to sales and support staff keeping communication open and honest—your efforts turned challenges into opportunities.

To Our Business Partners

Partnerships are forged in trust, and this year proved the strength of ours. Suppliers, distributors, and collaborators worked tirelessly to keep operations moving despite global headwinds. Your flexibility and shared commitment to long-term success made all the difference.

Looking Ahead

The tungsten powder and tungsten carbide markets may continue to evolve unpredictably, but we are confident in one thing: with the support of our customers, colleagues, and partners, we can face whatever lies ahead.

This year has reminded us that resilience is not built in isolation—it is built in community. For that, we are deeply grateful.

Here’s to a future shaped not only by the strength of these remarkable materials, but by the strength of the relationships that sustain us.

Buffalo Tungsten receives ISO 9001:2015 Certification

Achieving ISO 9001:2015 Certification Strengthens Quality in Tungsten and Tungsten Carbide Powder Manufacturing

We’re proud to announce that Buffalo Tungsten has achieved ISO 9001:2015 certification for the manufacture and distribution of tungsten and tungsten carbide based powders. This is a milestone that reflects our long-standing commitment to quality, consistency, and customer satisfaction.

For decades, we’ve focused on producing high quality tungsten and tungsten carbide powders that meet demanding specifications across many industries. ISO 9001:2015 certification demonstrates that our processes not only deliver reliable results but also meet internationally recognized standards for quality management.

Customer Satisfaction: The True Measure of Our Quality Journey

Although ISO 9001:2015 provides a valuable framework, our most meaningful indicator of quality has always been the trust and loyalty of our customers. Many of our largest clients—some of the most respected names in industries that depend on tungsten and tungsten carbide materials—have partnered with us for over 20 years.

Their continued confidence is the real story behind our certification. Long-term relationships like these are built on:

- Consistent powder performance across batches

- Fast, reliable distribution

- Responsiveness to evolving material requirements

- Transparent communication and technical support

ISO 9001:2015 helps formalize the quality practices we’ve refined through decades of customer-focused work.

What ISO 9001:2015 Means for Our Powder Manufacturing Operations

ISO 9001:2015 is the world’s leading quality management standard, requiring companies to demonstrate:

- Consistent and controlled manufacturing processes

- Robust quality assurance and traceability

- Proactive risk management and continual improvement

- A strong focus on customer satisfaction

For a precision-driven field like tungsten and tungsten carbide powder production, this certification validates our disciplined approach to process control, material integrity, and on-time distribution.

A Quality System Built for Continuous Improvement

Achieving ISO 9001 certification wasn’t a single project—it was an opportunity to elevate the systems we already had in place. Our team refined documentation, strengthened internal audits, and enhanced process controls across our tungsten and tungsten carbide powder operations.

These improvements ensure we remain adaptable, efficient, and positioned for ongoing innovation.

What This Certification Means for Our Customers

Our ISO 9001 certification ensures that customers can continue to rely on:

- Consistent tungsten and tungsten carbide powder quality

- Precision manufacturing supported by strict quality controls

- Improved traceability and documentation

- Streamlined distribution and dependable delivery schedules

It reinforces our ongoing promise: to deliver the highest level of reliability in every batch we manufacture and every shipment we send.

Looking Ahead

This achievement marks a significant point in our quality journey, but it’s only the beginning. As we continue to grow and improve, we remain dedicated to delivering exceptional tungsten and tungsten carbide based powders—and to building customer partnerships that last decades into the future.

Sandvik completes the acquisition of Buffalo Tungsten

In a press release issued Monday, 04 December 2023, Sandvik announced

"Sandvik has completed the previously announced acquisition of Buffalo Tungsten, Inc. (BTI), a leading US based manufacturer of tungsten metal powder and tungsten carbide powder, primarily operating in North America."

In a press release concerning the agreement to acquire Buffalo Tungsten on 26 October 2023, Sandvik said

"Sandvik has signed an agreement to acquire Buffalo Tungsten, Inc. (BTI), a leading US based manufacturer of tungsten metal powder and tungsten carbide powder, primarily operating in North America. The company will be reported within the business area segment Sandvik Machining Solutions (SMS).

"With the acquisition of BTI, Sandvik further expands its presence in the North American market and strengthens its regional capabilities in the component manufacturing value chain. The integration of BTI offers synergy potential, by optimizing materials sourcing and increasing the rate of locally produced tungsten metal powder, through its facility in Depew, NY, US. This will complement Sandvik’s already existing production of similar products at Wolfram in St. Martin, Austria.

"With the acquisition of BTI we take an important step in our strategic ambition to strengthen our presence in the North American market. BTI will enhance our regional capacity to produce tungsten powder locally in US, which will improve our competitive position,” says Stefan Widing, President and CEO of Sandvik.

“With BTI we will be able to better meet the customer demand which will give us great opportunities in North America. BTI’s contract for clean hydropower from the Niagara Power Project will also enable us to manufacture tungsten in a more sustainable way,” says Nadine Crauwels, President of Sandvik Machining Solutions.

"BTI was established in 1987, has 48 employees and is headquartered in Depew, New York. In 2022, the company generated revenues of about SEK 333 million. The impact on Sandvik’s EBITA margin will be limited. Impact on earnings per share will be accretive. The parties have agreed not to disclose the purchase price. The transaction is expected to close in the fourth quarter of 2023."

ITIA Membership

Buffalo Tungsten has applied for membership in the International Tungsten Industry Association (ITIA). We have filled out the membership application and also have letters supporting us from several member companies. Following the formal application process, the final step is a vote of the current members of the ITIA at the next annual general meeting. It will be in Brussels, Belgium in October. Tungsten is a small industry, therefore we already have business relationships with many of the member companies. As a result, we are hoping that the existing members will accept us into this esteemed organization.

ITIA Membership Goals

According to their website, the goals of the ITIA are

- to promote the use of tungsten and tungsten products

- to co-ordinate the extensive work programme of the ITIA Health, Safety and Environment Committee, including:

- regulatory and classification issues,

- monitoring proposed legislation,

- developing scientific data on the impact of tungsten on human health and the environment,

- in response to the EU's legislation "REACH", ITIA has set up a Tungsten Consortium which is open to Association members and non-members alike

- to organise regular meeting for the tungsten industry worldwide

- to collate from different sources, comprehensive statistics covering tungsten production, processing, consumption and end-uses and to circulate an annual statistical report to its members.

- to collate and circulate on a regular basis information relating to the ITIA's activities and to arrange for publication of a periodic newsletter

- to liaise and exchange information with other metal trade associations.

Refractory Metals Association

We have been a member of the Refractory Metals Association (RMA) since the beginning of 2021. This is a trade association of North American manufacturers. The purpose of this organization is "to promote and expand the markets for refractory metals."

Buffalo Tungsten has been producing tungsten powder products for 35 years. In addition to domestic sales, we sell tungsten powder in international markets, with sales in over 40 countries. We feel that our company is finally mature enough to be able to contribute to relevant trade organizations. As a result, we feel it is time to join the trade associations that allow us to help promote the industry and move it forward.

Buffalo Tungsten 35 Year Anniversary

Buffalo Tungsten recently celebrated our 35 year anniversary. A milestone such as this is an occasion to reflect on what got us to this point. There are several core values that have allowed our small private company to endure through the years. Here are a few of the things we feel have helped us achieve success.

First, Buffalo Tungsten maintains a strong focus on our customers. We do not make any fabricated tungsten products, so we have no internal demand. Our tungsten powder goes 100% into customer applications. We are not in competition with our customers, so we are able to focus on making powders that work for our customers without any conflict of interest.

High quality is a top priority in satisfying the needs of our customers. Our tungsten powder meets demanding customer specifications. Our quality assurance process assures conformance to physical and chemical requirements, such as

- Average Particle Size

- Particle Size Distribution

- Mesh Analysis

- Apparent Density

- Tap Density

- Chemical Purity

- Alloy Composition

The Extra Mile

In addition, we always try to go the extra mile to help our customers meet their production schedules. Buffalo Tungsten stocks many of the common powders our customers use, allowing us to provide short lead times. We are minutes from the Buffalo Niagara International Airport, and consequently we can get orders to the airport the same day to meet urgent requirements. We have made the trip many times on the way to the 35 year anniversary of Buffalo Tungsten.

Finally, competitive pricing is an important factor that allows us to achieve what we have. With a low cost facility and utilities we are able to provide value to our customers. We are always trying to increase efficiency in order to improve our competitive position.

In short, by putting the needs of our customers first we have made it our 35 year anniversary. After that long, we are still excited to continue to grow and improve. We look forward to seeing where the next 35 years takes us!

Russian Economic Sanctions

With the recent Russian actions in Ukraine, Russia is under economic sanctions by many nations. It is too soon to understand all of the impacts of these sanctions. Buffalo Tungsten is not reliant upon any Russian materials or supplies. We can operate at full capacity for tungsten powder production without any materials from Russian entities. We do not expect current or future Russian economic sanctions to effect our business.

There are active tungsten mines in Russia. They operate primarily in the far eastern part of the country, but there are tungsten operations in western areas as well. There are mines actively producing tungsten concentrates. The materials are available on the open market. There are plants in the country that treat and process these tungsten concentrates into various intermediate forms and products.

Buffalo Tungsten has purchased materials from Russian entities at times. We have no contracts in place for 2022 or beyond at this time to purchase materials reliant on Russian companies. Therefore, we feel that the Russian economic sanctions will not have an adverse impact on us.

Buffalo Tungsten's supply chain is diverse, but we still actively manage our sources of materials to insulate us from uncertainty. As a result, we have reduced our dependence on countries we feel present risks. We will continue to evaluate where we source raw materials. This will allow us to continue to provide a consistent supply of tungsten powder products to our customers.

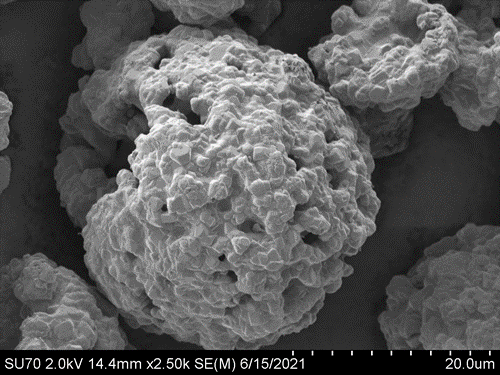

WC Thermal Spray Powder

Buffalo Tungsten's latest R&D project for WC thermal spray powder has led to some big improvements. We plan to launch the enhanced powders in the first quarter of 2022. Our new and improved products will help all who use our material see better results in their surface coatings.

The ASM International Thermal Spray Society has a page that describes the thermal spray process. It mentions that the powder is brought to a molten or semi-molten state and sprayed onto a part to restore and rebuild it or to provide a more protective surface coating. It can better protect the part from things like wear, abrasion, or corrosion. With this in mind, it is easy to see how the fine-tuning of our process will make a big impact on results.

Improvements to WC Thermal Spray Powder

Because the shape of the powder is so important, we have made our powder more spherical. As a result, our thermal spray powders flow better through the HVOF guns that apply it. Better flow through the gun allows for better application of the powder.

The deposition efficiency has also improved using our new process. This means that more of the powder ends up on the part and less on the floor. There is less waste and a more consistent surface coating.

In addition, the powders we are producing after the changes have a higher density. This gives the parts better wear and abrasion protection following a thermal spray coating.

Buffalo Tungsten is excited to introduce these changes. As with our other products, we manufacture WC thermal spray powder at our factory in Depew, New York. We welcome thermal spray shops to try our new powders and provide us with feedback. We listen carefully to our customers and always strive to make our thermal spray powders better meet your needs as we move forward.

Veterans Day

The US Department of Veterans Affairs (VA) has a page about the history of Veterans Day in the United States. The armistice to end the fighting of World War I went into effect at the 11th hour of the 11th day of the 11th month of 1918. As a result, we celebrate the veterans of our armed services each year on November 11th. At this time, Buffalo Tungsten would like to wish a happy Veterans Day to all who have served.

Unfortuantely, World War I was not the "war to end all wars," as many had hoped at the time. There have been many wars fought since then. As a result, it has been important to maintain our military to preserve our freedoms. Those who serve not only protect our nation, they also receive training that benefits their future career prospects.

At Buffalo Tungsten we encourage veterans to apply for job openings. We find that the skills they gain in military service help our company.

Reasons to Hire Veterans

The VA points out several reasons to hire veterans. The following ideas are from the VA:

- Working well in a team. Teamwork is an essential part of daily life and is the foundation of safe military operations.

- Having a sense of duty. Responsibility for job performance and accountability for completing missions are something to take pride in.

- Experiencing self-confidence. Holding a realistic estimation of self and ability based on experiences.

- Organization and discipline.

- Possessing a strong work ethic. In the military, the mission always comes first.

- Having the ability to follow through on assignments, even under difficult or stressful circumstances.

- Possessing a variety of cross-functional skills, such as extensive training on computer programs and systems, interacting with various people with different skills to accomplish a task, and coordinating and troubleshooting problems in novel and known conditions.

- Solving problems quickly and creatively.

- Adapting to changing situations.

- Able to follow rules and schedules.

On this Veterans Day Buffalo Tungsten is grateful to those who have served and currently serve in the armed forces of the United States. Without their service our company would not be able to operate ias we have for the past 34 years. We recognize and value the contribution of the US military on our ability to produce tungsten powder in a nation that is free. Our political and economic stability is a result of their dedication and service. We offer our thanks and well wishes for a happy Veterans Day to those who have earned that title of respect.

Buffalo Tungsten LED Lighting Upgrade

Buffalo Tungsten has recently upgraded lighting in our factory to LED fixtures. The change saves a substantial amount of electricity. "LEDs use up to 90% less energy and last up to 25 times longer than traditional incandescent bulbs" according to a US Department of Energy information page on LED lighting. It has also made a noticeable difference in the brightness of our factory.

There is a bit of irony in a tungsten factory is making an LED lighting upgrade. One one of the most widely known applications of tungsten is as a filament for the incandescent lightbulb. Some of the history of tungsten in lighting is in this article from the Institute of Electrical and Electronics Engineers. With the advent of LED lighting, the incandescent bulb is largely a thing of the past. General Electric closed their tungsten powder plant in Euclid, Ohio several years ago. For many years this plant made tungsten wire for the iconic GE light bulbs, which trace their roots back to Thomas Edison.

LED Lighting Upgrade More Efficient

This article from LED Lighting Info explains why the tungsten filament is inefficient. It states "around 90% of an incandescent bulb’s electricity supply is wasted as heat, with a measly 10% actually being used to create light. This is because the tungsten filament inside an incandescent bulb needs to be heated to around 4600 degrees Fahrenheit to produce light." It further goes on to explain that "when a 100-watt lamp is turned on, 100 watts of electrical energy is converted to 100 watts of light and heat. As incandescent bulbs are incredibly inefficient and have a luminous efficiency of 2-3%, this usually translates as 98 watts of heat and 2 watts of light."

The LED lighting upgrade also increases safety in our plant. Forklifts are easier to see as they move about the factory floor. Production equipment is easier to load and unload. It is easier to read tags and labels on our inventory, reducing eye strain.

While the tungsten powder market remains strong, it has shifted from lighting to other applications. With our transition to LED bulbs and fixtures complete, we sadly leave the tungsten filament behind.